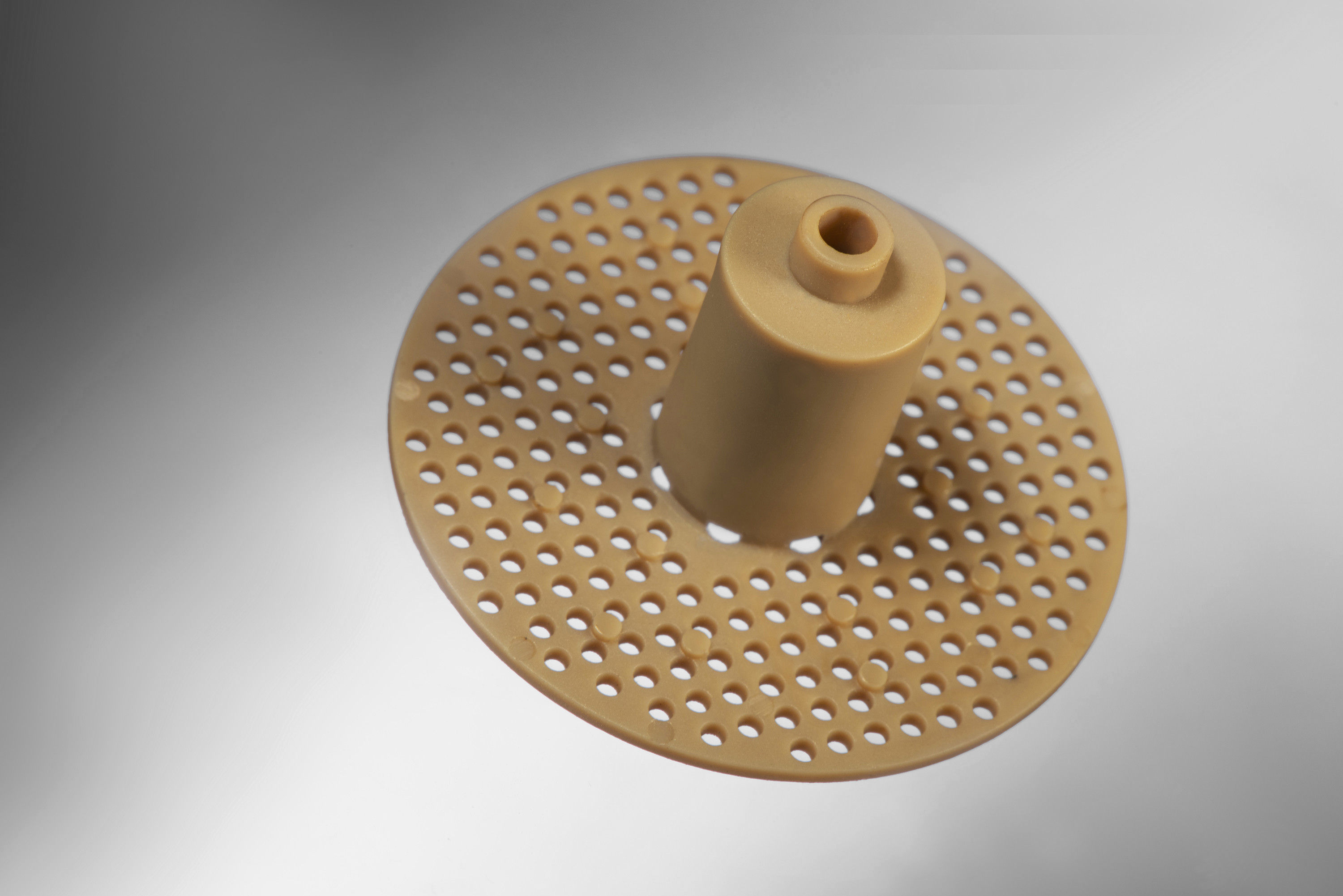

Product range

Injection moulded parts

Introduction

The production of complex technical components from high-performance plastics using the injection moulding process is one of our core competencies. Whether it is an annual quantity of 200 or 10 million pieces, our modern machinery is perfectly equipped.

Materials

We process all unfilled and reinforced thermoplastics except PVC and specialise in PEEK, LCP, PPS, PSU, PPA (PA HT) and fluoropolymers (e.g. Teflon PFA, PTFE, PVDF), among others. Depending on your requirements, we can produce customised compounds or colours for you and will be happy to advise you on material selection.

Manufacturing options

Sophisticated production methods combined with precise injection moulding tools guarantee accuracy and performance. We also have extensive experience in overmoulding inserts such as steel, glass, brass or plastic. We are also happy to undertake post-processing such as printing, painting, ultrasonic welding, mechanical reworking and the assembly of your complete components.

Machinery

Our modern machinery is constantly being updated and includes injection moulding machines with clamping forces of 180 to 1100 kN. We produce thin-walled parts with position-controlled injection units; for high-precision, fast injection, if necessary with pressure accumulators. Depending on the technical requirements, we use all-electric or hydraulic machines with horizontal or vertical injection or clamping units, which can positively influence the fibre orientation, for example. Parts or sprues are automatically removed and deposited using removal robots.