Product range

Part labelling

Introduction

Components are labeled for different reasons. The requirements for the type and method of labeling are just as varied. KUNDERT offers different types of labeling depending on the requirements.

Type of labeling

If you would like to label your plastic components with your company logo, an article number or a data matrix (QR code), we offer you the following options.

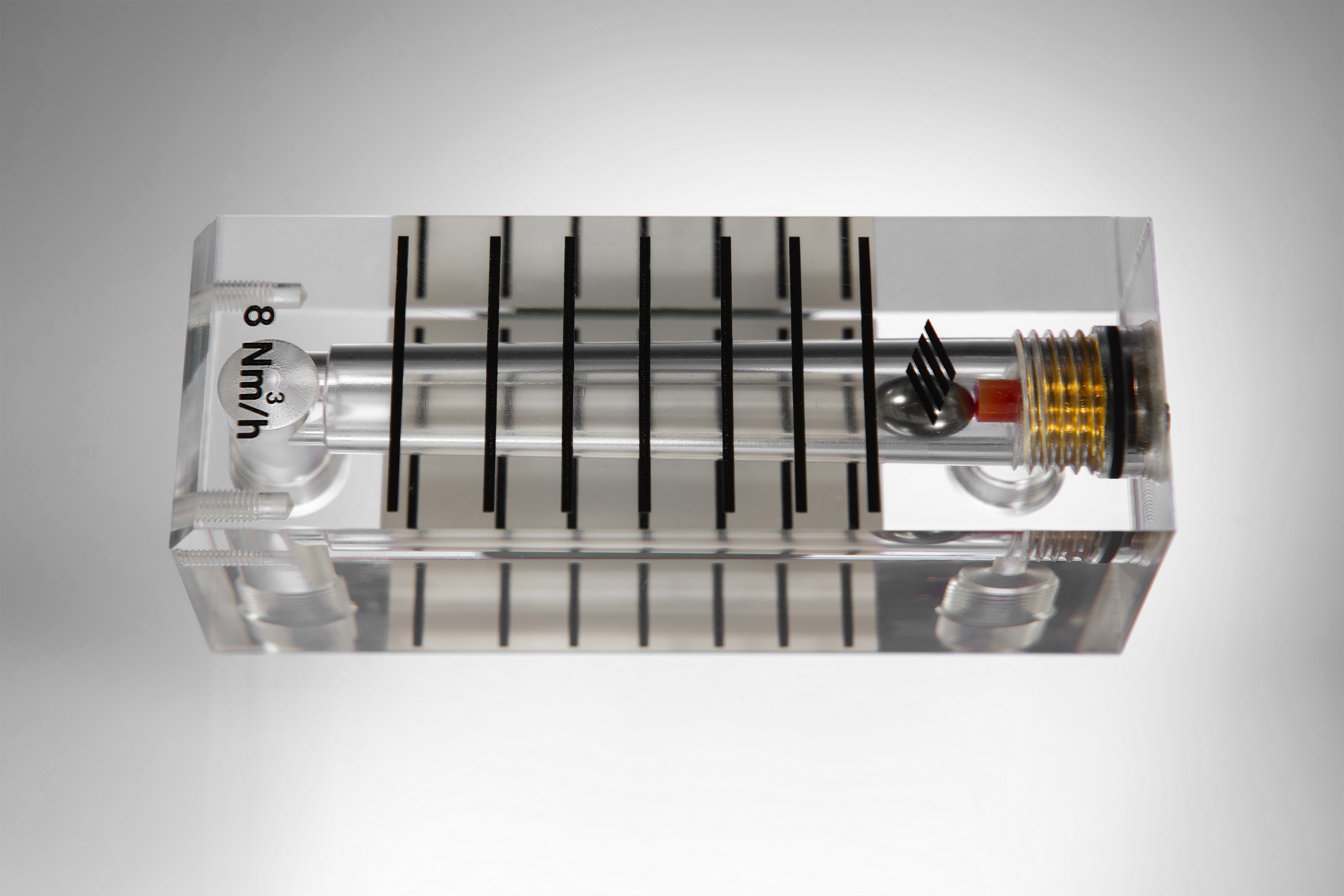

Laser marking

The possibilities of laser marking are almost unlimited. Company logos, all kinds of information in text form or data matrices such as QR codes can be created. Laser marking does not damage the material and is therefore also suitable for sensitive parts. Very high resolutions and intricate contours can be implemented on both flat and curved surfaces.

Pad printing

Pad printing offers even greater design freedom, as multi-colored lettering is also possible. As with laser marking, curved surfaces can be realized to a certain extent.

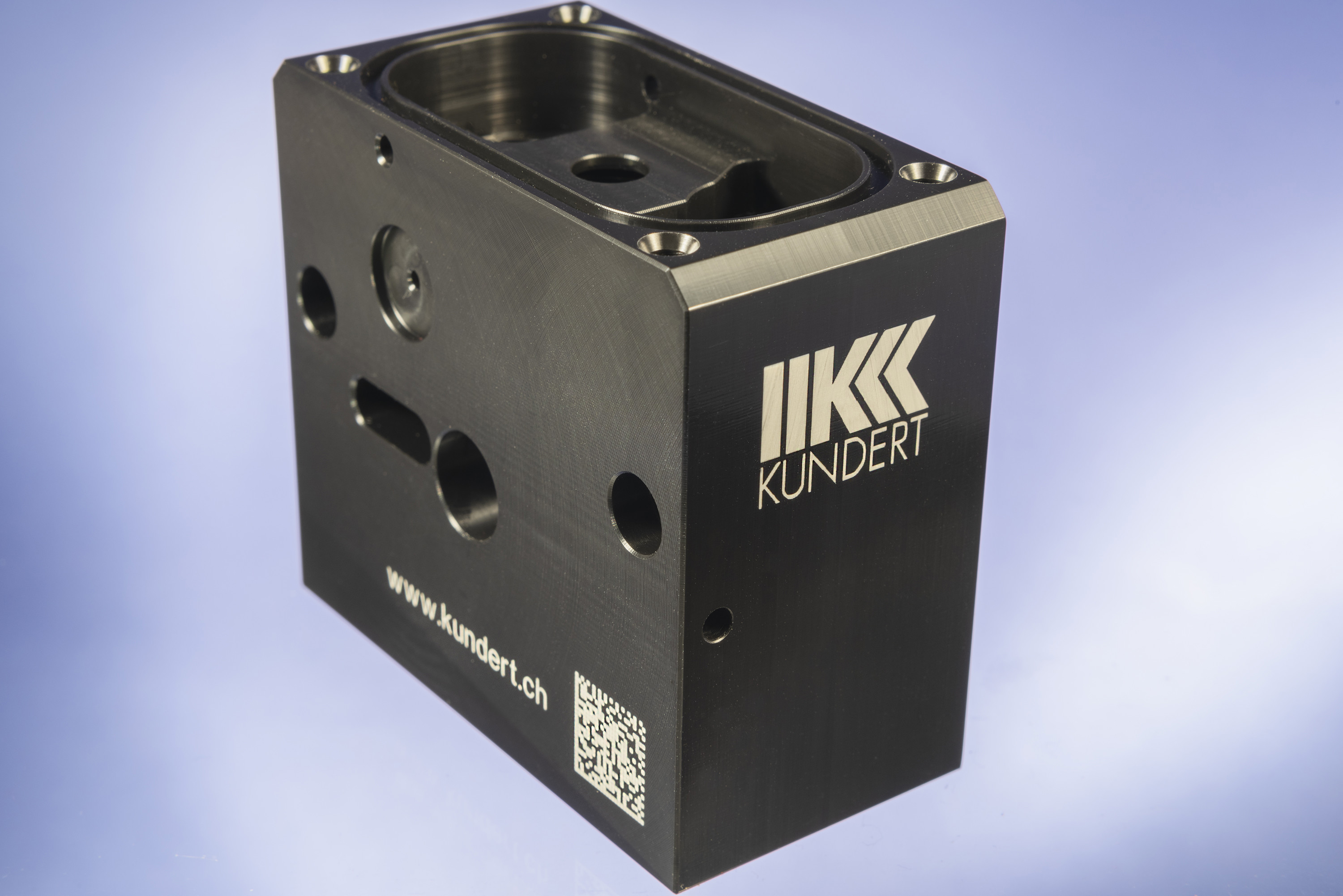

Mechanical engraving

Mechanical engraving can be applied to almost all materials. However, as with the other two types of marking, the component geometry must allow engraving. For example, very thin-walled component contours cannot be marked. Mechanical engraving can be used to implement company logos or inscriptions such as article numbers, drawing numbers or batch numbers. However, data matrices are not possible as these cannot be read with a suitable device.