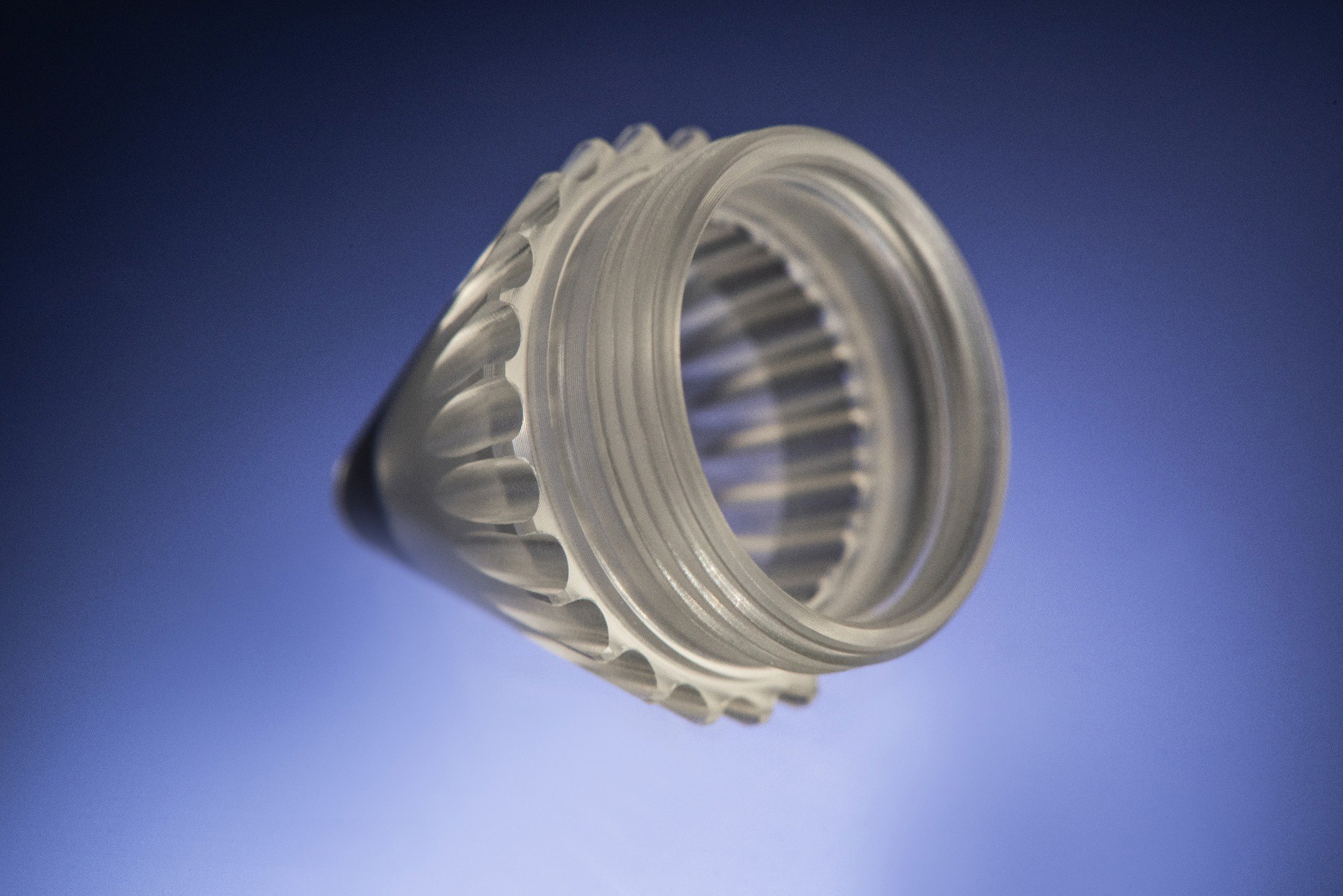

Machining and injection moulding

KUNDERT offers the unique opportunity to obtain machined and injection-moulded parts from a single source. With our two state-of-the-art production departments for machining and injection moulding, we always find the ideal manufacturing process for every phase of a product's life cycle.

KUNDERT has specialised in the manufacture of machined plastic finished parts for over 60 years. Around 40 machines are available in the company's own production department in Jona. State-of-the-art, automated turning and milling centres can be used to efficiently produce everything from individual items and prototypes to large series, from the smallest complex parts to large-volume workpieces.

Since the takeover of Hilty Engineering AG in summer 2024, KUNDERT has had its own injection moulding production including toolmaking at the Uznach site. On 13 modern injection moulding machines, complex small parts up to parts with a projection area of a postcard can be produced from a quantity of 200.

Depending on the stage a component is at in its product life cycle, either a machined or an injection-moulded version may make more sense. It often makes sense for parts to be produced by machining in the prototype phase. However, if the production batch size in the series phase exceeds a certain threshold, injection moulding is significantly more efficient and cost-effective. As KUNDERT combines the two worlds of machining and injection moulding, our customers do not need to change the source of supply in such situations.

Our specialists will be happy to assist you when it comes to clarifying technical feasibility or finding the most economically viable manufacturing process.

You can find more information about our manufacturing options on the following pages: