Produktangebot

Kundenspezifische Profile und Rohre

Einführung

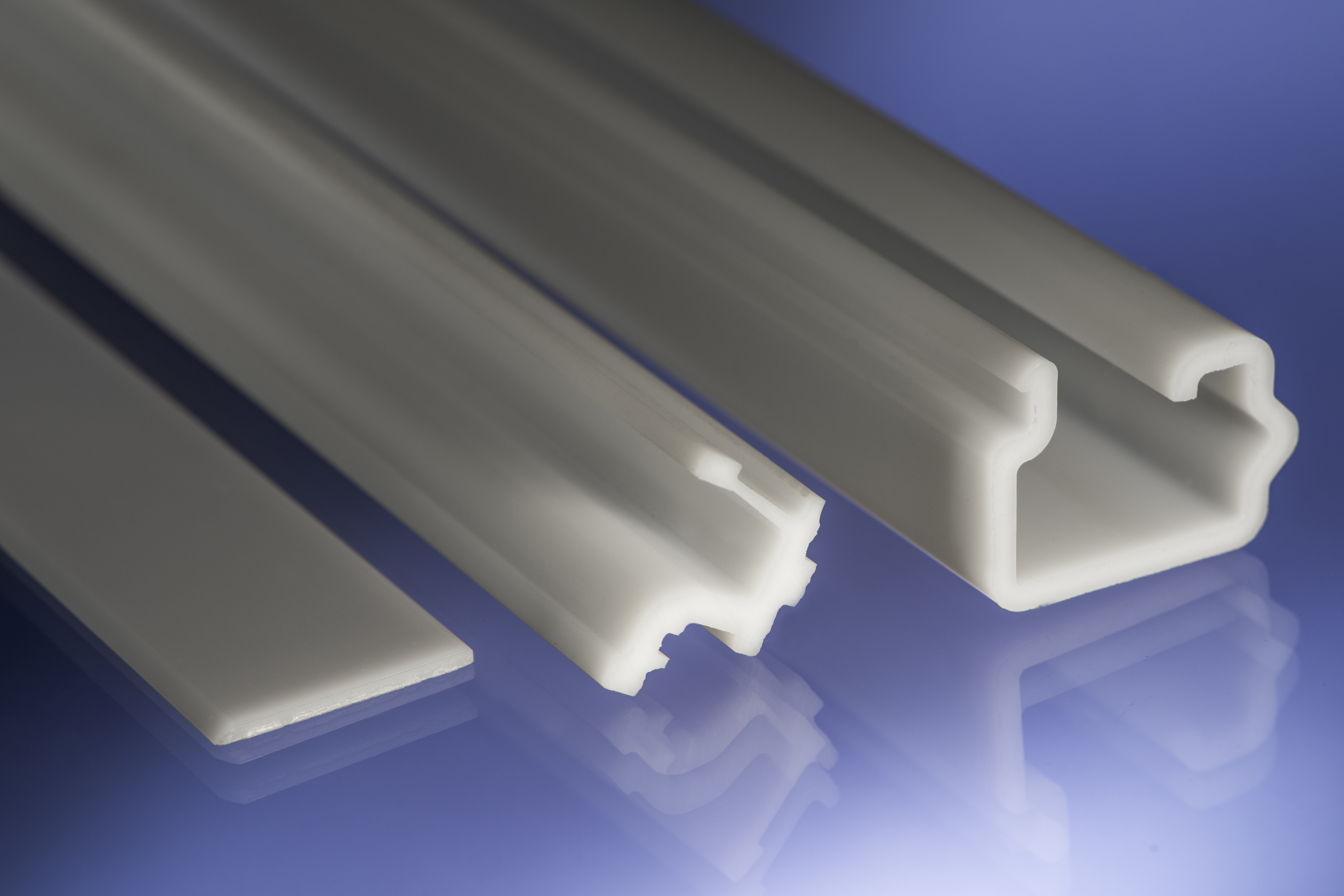

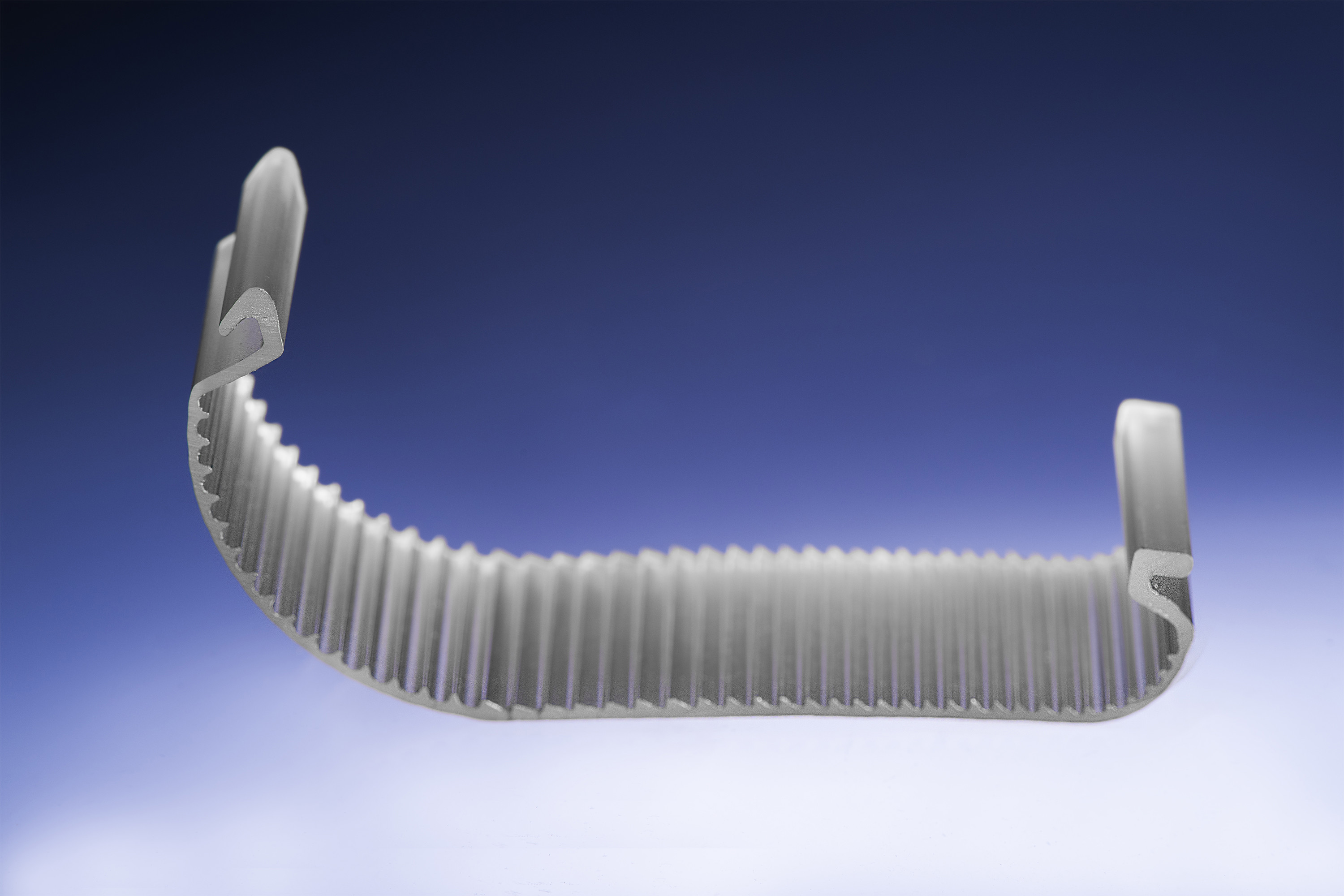

KUNDERT ist spezialisiert im Angebot von Profilen und Spezialrohren aus Thermoplasten für die Industrie, Medizin- und Lebensmitteltechnik. Dabei werden Geometrie und Werkstoff genau auf die jeweilige Anwendung abgestimmt. Profile und Rohre werden im druck- und temperaturgeregelten Extrusionsverfahren hergestellt. Bei diesem Fertigungsverfahren, wird der Werkstoff aufgeschmolzen und endlos durch eine Düse in Form gepresst.

Einsatzgebiete

- Vollprofile

- Hohlkammerprofile

- Besonders dünnwandige Profile mit Wandstärken von 0.4 bis 0.5 mm

Galerie

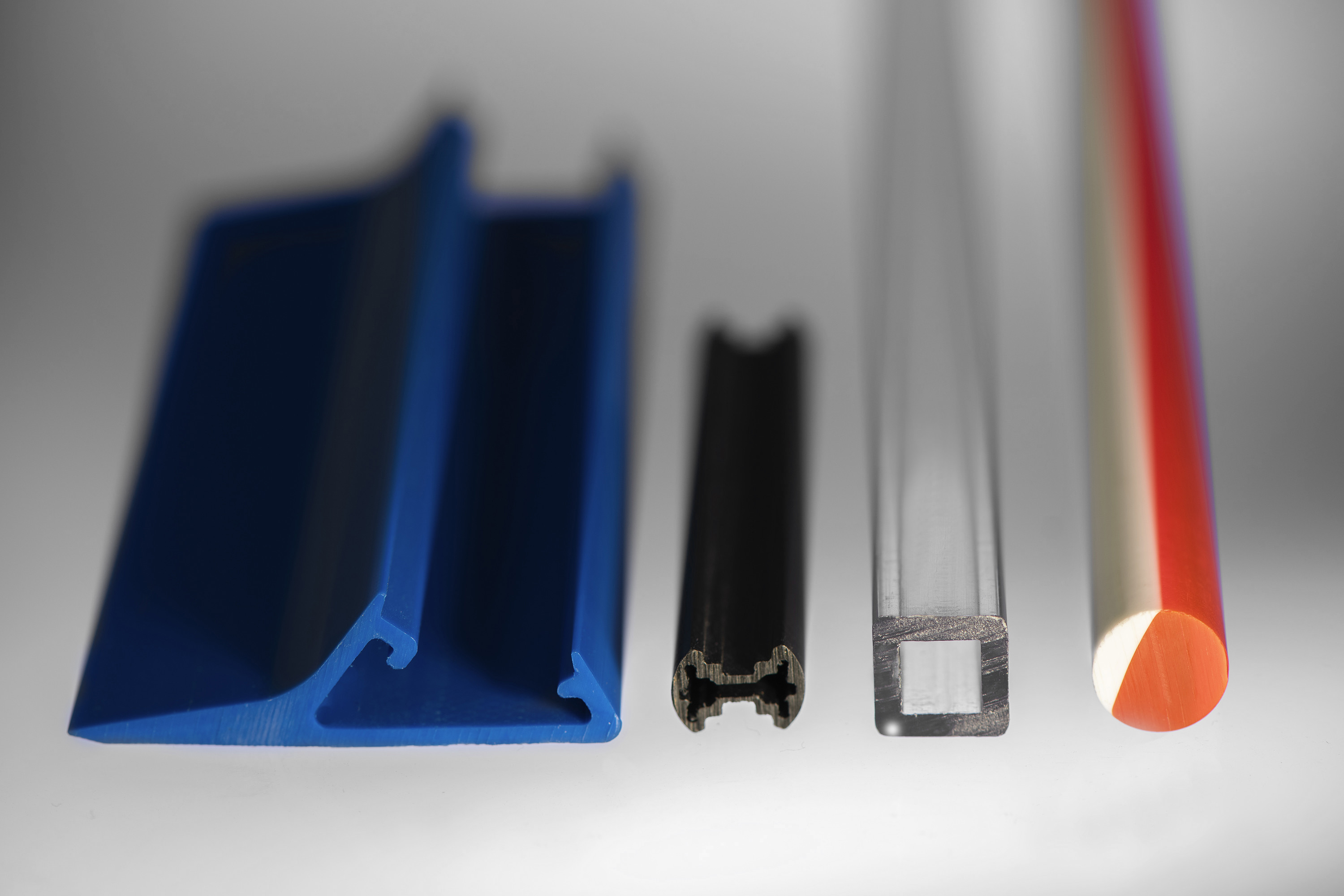

Breites Angebot an verschiedenen Werkstoffen, Geometrien

Zusätzlich können Verstärkungsstoffe wie Metalle eingearbeitet, Kunststoffe mit verschiedenen Eigenschaften im Ummantelungsverfahren verbunden oder Hart-Weich-Verbindungen, zum Beispiel für Dichtlippen gefertigt werden.

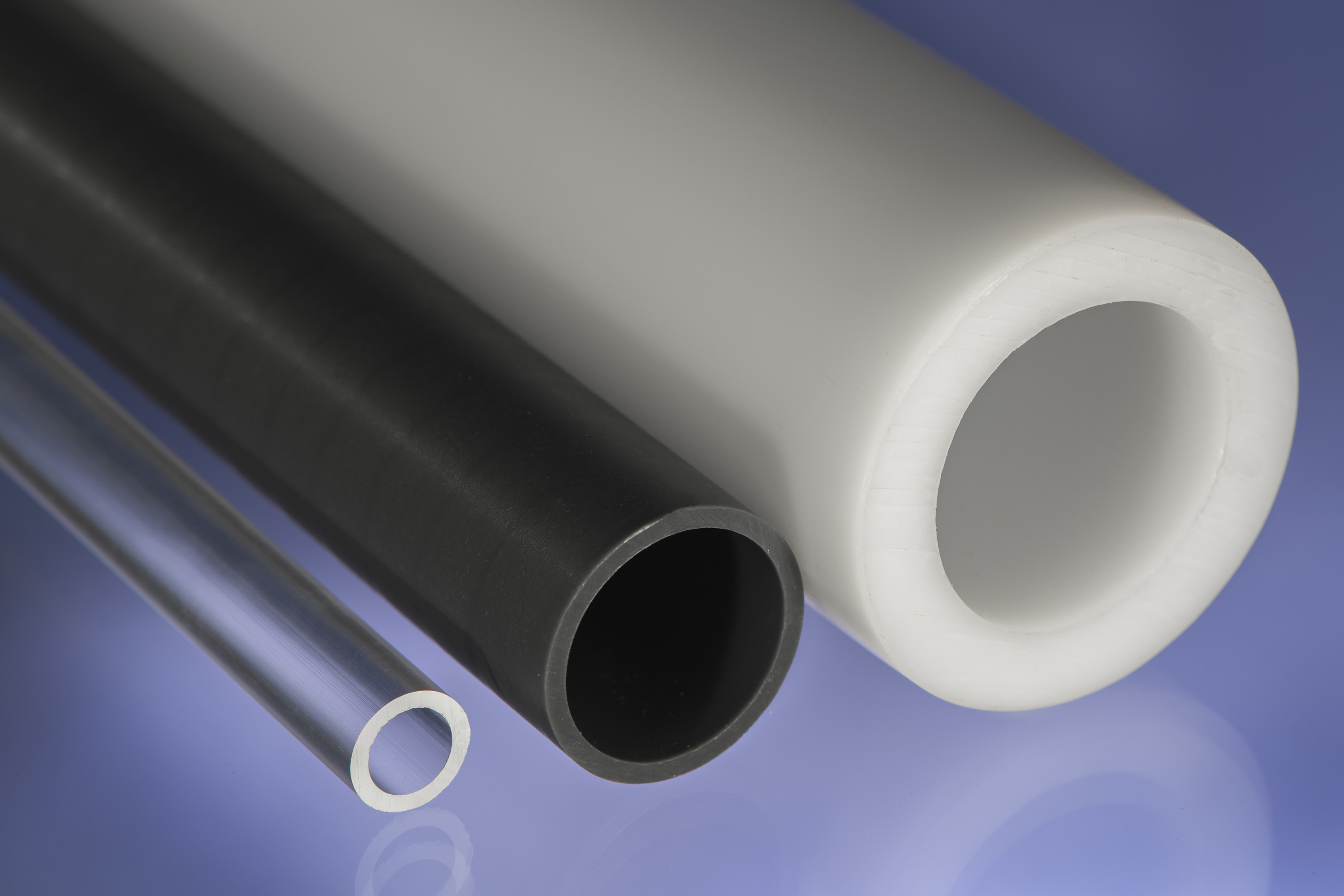

Spezialrohre mit einem minimalen Durchmesser von 2 bis 3 mm und einem maximalen Durchmesser von 90 mm können realisiert werden. Bei der Wanddicke ist jede Abstufung von 0.3 bis 20 mm realisierbar.